14 September 2010

TopSolid’Cam reduces machine running times.

For ROKU Mechanik GmbH, a company specialized in the complete machining of complex A-parts (a classification of very high quality parts), short machine running times are more important than short programming times. With TopSolid, the company is able to simulate and optimize not only the tool paths but also the machining duration. ROKU manager, Roland Kuhnhaus, is anticipating total cost reductions to the tune of at least 50 per cent thanks to the use of the Missler Software solution.

ROKU Mechanik GmbH, based in Unterschneidheim in Germany, is a traditional manufacturing company that handles the complete machining of complex components with all the usual surface coatings for its customers, as well as providing customers with logistical support. “We supply ready-to-install parts directly to clients’ assembly workshops, often as complete parts sets with 200 to 300 separate parts in the Kanban bin,” explains company manager, Roland Kuhnhaus. In these cases, the company also coordinates the procurement of catalogue parts and the manufacturing of stamping and laser parts that would normally be put out to subcontractors. ROKU specializes in the manufacturing of “A-parts” for vehicle manufacturing, propulsion technology, aerospace, medical technology and the optical industry, which are normally produced in batch sizes of up to 10 000 parts per year. The company, which currently employs 140 staff, machines the balance shaft housing, for example, for the engines of a major German car manufacturer and mills the aluminium casing of professional cameras and operation microscopes for a German optical devices manufacturer. This to some extent involves safety-related components that are delivered directly to the assembly line, with high process requirements in terms of quality and reliability.

In order to secure a seamless transition from prototype to mass production, ROKU essentially manufactures prototype parts on mass production machinery, with all the necessary production equipment and fastening devices being designed in-house. “We must be capable of accommodating the mass production of even highly complex parts in as short a turnaround time as possible,” says Mr. Kuhnhaus, in describing one of the challenges facing his company. “For this reason, part manufacturing today runs in parallel with part development – parts which may, if necessary, be scrapped if errors arise. This is a risk that the client is prepared to accept in order to get his products to market quickly.”

ROKU has done much in recent years to standardize the machinery pool, replacing the many different milling machines and lathes with highly complex machining centres comprising up to eight axes, for comprehensive stock removal, whatever the material being machined: steel, titanium, aluminium, cast/forged parts or plastics. The variety of different controllers has also been reduced to include just the Fanuc and the Okuma controllers. Standardization allows for flexible production planning, since CNC programs and devices can be used in conjunction with practically all machines, although powerful CAD/CAM tools are also needed in order to fully exploit machine potential. “If you cannot simulate the machining visually on a computer, the increasing complexity of parts generates machine downtime for running-in and tool changes, and no one can afford this any more,” states Mr. Kuhnhaus emphatically.

Strengths for lathe work

In the light of the growing complexity of machines and of the parts to be machined, ROKU opted at the end of 2005 to introduce a 3D CAD/CAM system. Previously, the machine operators already used to prepare the machining offline, but using a traditional 2D editor for the manufacturing drawings. This had the drawback that they could neither calculate the raw part geometry and stock removal nor recognize the projecting edges. Collision analysis is therefore important for ROKU, since many parts have such complex forms that special apparatus needs to be developed to secure them, possibly leading to collisions during the machining process with the tooling and support. Various CAD/CAM systems were considered that were on a par with TopSolid in terms of milling programming, but what ultimately proved decisive for the choice of TopSolid was the excellent support for complex multi-function machining, as Andreas Hammele, CNC programming manager, is keen to stress: “On multiple axis machines with double spindles, it is no longer possible to calculate the synchronous breakdown of the individual operations in your head. We were therefore looking for a solution that allowed us to simulate the synchronization of the machining on the computer, so as to prevent us having to find out on the machine itself that the breakdown didn’t work and then having to rearrange all the tools. We also needed a powerful CAD module for designing our devices.”

The integrated CAD/CAM solution from Missler Software is now running in Unterschneidheim on six PC workstations in all, under Windows XP. Three of them are equipped with the TopSolid’Design software, the TopSolid’Cam ME module for 3-axis mill programming and the TopSolid’Cam lathe module, and the three others with just the CAD software. They are mainly used for the design of production equipment, as Mr. Hammele says: “Parts with complex forms cannot generally be machined with standard clamping fixtures, and so, for the car industry for example, we often need to design special fastening devices and handling facilities.”

ROKU needs the powerful CAD functions not only for the design of fastening devices and production equipment, however. Manufacturing specialists are being called upon more and more to support their customers in product development and submit proposals as to how parts can be produced more cost-effectively or how the weight of the parts can be reduced without the need for costly manufacturing operations. “The product designer, indeed, often has no idea of how we are to machine the part and, above all, how we are to mount it. The costs of producing an elaborate clamping jig can be brought down dramatically if we can have an influence on the workpiece holder design,” explains Mr. Kuhnhaus.

Support with graphic video clips

The new CAD/CAM solution was implemented some two years ago by the Missler Software sales partner, AdeQuate Solutions from Lahr, who also provided training for the operatives and continues to provide troubleshooting support today. The users are very happy with the support, as Hammele is keen to underline. Within 24 hours they get answers to their support queries, often in the form of video clips that demonstrate the correct way to proceed. ROKU also makes use of the remote maintenance service that the systems vendor offers its customers. Basic training in how to use the CAD and CAM functions took some two to three days for each, and the users then had around four to six weeks to put into practice what they had learned, before embarking on several days of advanced training. After around eight weeks they had become so familiar with the CAD system that they could use it with confidence. Familiarization with the CAM functionality took a little longer, since the programmers also had to learn how to incorporate their tools in TopSolid.

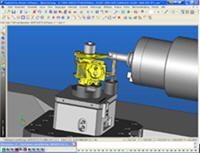

The representation of the tools, machines and fastening devices is a key prerequisite for realistic simulation of the CAM machining. Today, at ROKU, no new milling or turning program is generated without at the same time designing the necessary tools. This involves storing all the cutting parameters so that the machining time for the individual operations can be calculated fairly precisely. The machines, too, had to be modelled initially in TopSolid, with operators from AdeQuate Solutions handling the task of representing the work sequences in the models. They also adapted the post-processors to the Makino and Okuma machining centres, a large number of which are in use at ROKU.

Simulating the machining steps

When available, ROKU today obtains 3D data sets of the components to be machined from its customers, normally in a neutral data format such as STEP or IGES. The users import this data into TopSolid, where they often still require some post-processing. “The problem is that we essentially manufacture and also program using the mean tolerance, but not all customers design in this way. This means that the converted data needs to continually be adapted,” says Mr. Hammele. If the customer is not yet designing in 3D or is unable to provide STEP data, the operators must first of all produce a 3D product model using the 2D drawings. They then define the raw parts geometry, which serve as the basis for the design of both fastening devices and production equipment. The 3D models of the clamping jigs can be used directly for the simulation of the machining programs.

On the basis of the raw parts and component geometry, the material for removal can be determined. The CAM programmer determines how and with which tools it is to be removed, with the system offering specific suggestions regarding the machining strategy. After each machining step, the raw parts geometry can be updated, so that the user is able to see at a glance where material remains. The software offers the possibility of defining reusable machining cycles for frequently occurring geometry elements. Such automation features are, however, of subsidiary importance for ROKU, as Mr. Hammele points out: “For us, the focus is clearly on the optimization of the machining times. We need to see how we can achieve the estimated machining times and so we concentrate more on the programming.”

The optimization of machining times is an interactive process. Using material removal simulation, the user is able to recognize which machining operations require the most time and is able to make corrections to suit; for example, by choosing a different machining strategy or else pre-roughing with a larger tool before machining with a smaller one. In Mr. Hammele’s opinion, the simulation functions are some of the main strengths of TopSolid since they allow you to see quite precisely how long the individual operations last and how they can be optimally distributed among the various axes and spindles.

Reducing machining times

Since the simulation makes it possible to reliably determine the left-over material and possible collisions, the machine operators can concentrate when running in the programs on the aspects that cannot be simulated, or which are disproportionately complex to simulate on the computer (for example, the effects of the physical forces or the behaviours of particular high-performance materials). “The craftsman working on the machine will always be responsible for making that last vital difference,” says Mr. Kuhnhaus with conviction. “Even with the same material, the circumstances are never identical. A cutting medium that works well with one part may suddenly present problems in a different component geometry. The experience of the operator must therefore constantly be brought to bear in the machining process.”

Thanks to the improved quality of the CNC programs, the running-in times at ROKU have fallen significantly. There are fewer machine errors that can generate unnecessary extra costs. It has also been observed that the machine running times have been reduced through the optimization of the CNC programs, although it is hard to quantify precisely the savings this offers. This is particularly the case inasmuch as the introduction of the system has not entirely been concluded as of yet. “I’m assuming, however,” says company boss, Roland Kuhnhaus, “that in the final upgrade stage, when all the machines have been mapped and all post-processors adapted, a reduction of the program costs to the tune of 50% plus X will be possible, where X will increase in proportion to the increasing complexity of the component to be machined.” ROKU is looking forward to additional savings potential through the introduction of product data management, which promises more efficient administration of the many devices and production equipment.

Need more information