28 April 2025

The TopSolid Integrated Digital Factory Suite continues to expand, simplifying design and enabling automated, accelerated production within a fully collaborative environment.

Each year, TOPSOLID SAS invests nearly 20% of its revenue into R&D and enhances its TopSolid product line with hundreds of improvements and new features inspired by feedback from partners and customers. The TopSolid Integrated Digital Factory Suite continues to expand, simplifying design and enabling automated, accelerated production within a fully collaborative environment.

TopSolid’Design

TopSolid'Predict: predictive intelligence that anticipates needs and suggests commands perfectly suited to each context

Automated backups and vaulting without interrupting work

Profile kits for automatic, standardized, and perfectly adjusted fastenings

New generation PDM tree for simplified document access

Automatic exceptions for generating clear and precise drawings

TopSolid’Cam

Simplified and faster creation of polygonal operationsNew features for easily managing all steady rest elements and movements

New continuous 5-axis finishing strategy

Fine-tune machining with residual toolpath control

Cutting-edge robotics offering versatility, simplified programming, better adaptability, and advanced machining path simulation

Smoother communication between the programming office and the shop floor

TopSolid’Virtual

Simplified navigation thanks to dynamic modesNew teleportation tool that automatically detects accessible surfaces

Stunningly realistic outdoor environments with real-time shadow and light visualization

Customization of 3D library elements

Automatic detection of physical geometry to speed up object placement

TopSolid’Steel

Full control of stringers to create custom staircasesReady-to-use profile kits

Intelligent entity detection to maximize the use of 3D scans

Possibility to simultaneously modify multiple profiles or component inclusions

Optimized performance and enhanced responsiveness for daily operations

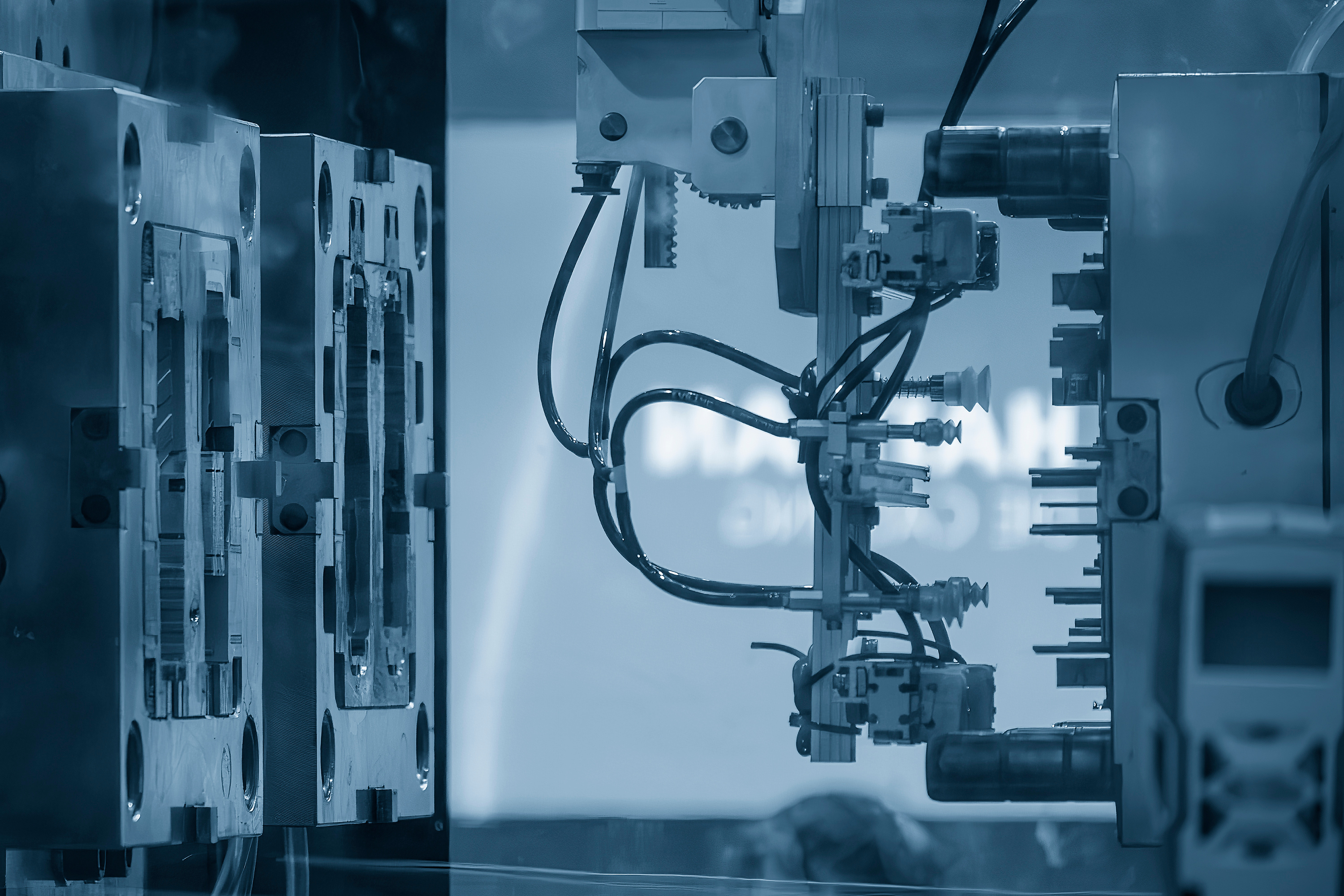

TopSolid’Mold

Automatic generation of shadow curves to accurately identify critical demolding areasParting line assistant for reliable mold design

Automated tool movements

Optimized cooling circuit design

Double-component wells for better management of complex cooling circuits

TopSolid’Wood

Enhanced user interface and functionalitiesIdentification views to highlight key design elements

Effortless customization

Tailored distribution for optimized pre-studies

Automation of linear profile implementation

TopSolid’Cut

Fast checking of prototype parts before launching productionOptimized cutting paths with alternating parts functionality

Accelerated part preparation with machining propagation

Automation of machining documentation

Increased flexibility for perfectly adjusted machining

TopSolid’Inspection

Simplified integration of files with various formats and structures into a single inspection projectOptimized management of non-conforming dimensions and rejected parts

Limited and secure access to your projects

Control plan that adapts to workshop contingencies

Precise and transparent tracking of every version of your inspection project

TopSolid’ShopFloor

New dashboard for a clear and optimized overviewNew Measuring Manager module to optimize each management step

Management of regrinding to optimize costs and extend tool life

Advanced filtering

Integration of TopSolid’Cam and Program Manager

TopSolid’PartCosting

Optimized batch production for maximum profitabilityAccurate and customizable time unit

Material characteristic search for quick identification of similar parts

TopSolid’ERP

Integration of a measurement recording moduleIntelligent scheduling

Creation of manufacturing orders

Introduction of dark mode for better visual comfort

Centralized management of FAI (First Article Inspection) files

“We are proud to present our 2025 innovations! As every year, our experts have developed new features across our products to improve usability and enhance the customer experience.”

— Richard Lamure, President of TOPSOLID

Need more information