Create polygon turning operations in record time

TopSolid'Cam 2025 redefines polygon turning, delivering unmatched speed, precision, and simplicity:

- Automatic recognition of the number of flat surfaces.

- Automatic tool orientation.

- Simplified axial or radial machining.

- Integrated TopSolid simulation.

Experience the power of advanced automation and unlock new levels of productivity!

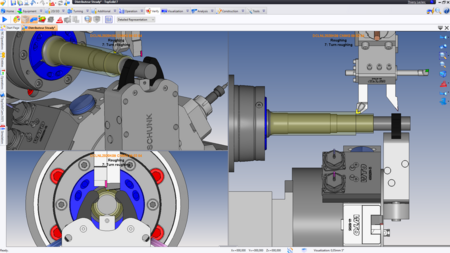

Master steady management for optimal precision

Take full control of every aspect and movement of your steady:

- Seamless simulation of opening and closing actions.

- Automatic stock recognition.

- Optimized turret-mounted steady management.

Elevate your machining performance with precise, intuitive, and reliable control!

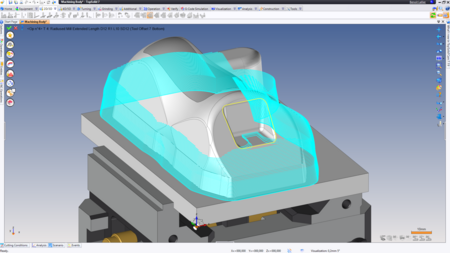

Boost your efficiency with the new continuous 5-axis finishing strategy

- Streamline your processes with significantly reduced programming and machining times.

- Experience a simple, intuitive interface designed for all skill levels.

- Take advantage of exceptional adaptability to handle any geometry, no matter how complex.

- Achieve perfect finishes in record time.

Harness the power of speed, simplicity, and precision to deliver outstanding results on every project!

Refine your machining with residual path command

Enhance your machining processes with advanced residual path command:

- Preview residual paths before final validation, ensuring full control.

- Easily adjust parameters and tools, with options for both 3-axis and 5-axis remachining.

- Machine only untouched areas, eliminating unnecessary rework of already processed paths.

- Quickly generate all additional operations with just a few clicks.

Increase flexibility and efficiency to handle even the most complex areas!

Redefine your machining methods with the power of robotics

TopSolid'Cam 2025 allows you to revolutionize your machining methods by seamlessly integrating cutting-edge robotics:

- Versatility: Control industrial robots for milling and drilling operations, whether on tool holders or part holders, on rails, or paired with a rotary table or 5-axis table.

- Simplified programming: Enjoy an intuitive interface that ensures optimal precision at every stage.

- Adaptability: Easily switch robotic configurations to suit your specific needs.

- Advanced path simulation: Visualize your robot’s movements for total control and flawless results.

Revolutionize your processes with smooth, high-performance robotics technology at your fingertips!

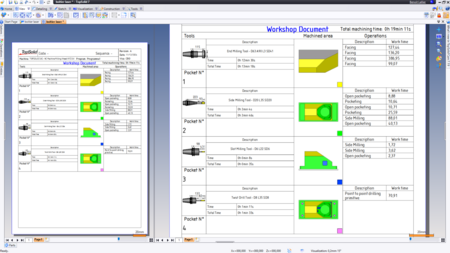

Streamline communication between the Programming Department and the Workshop

- Simplified tracking: View the list of successive operations performed by the same tool at a glance.

- Rapid validation: Immediately identify machined areas after multiple operations to make precise adjustments.

- Improved readability: Leverage color-coded tools for clearer, error-free programming.

These innovations strengthen communication and enhance the efficiency of your production!